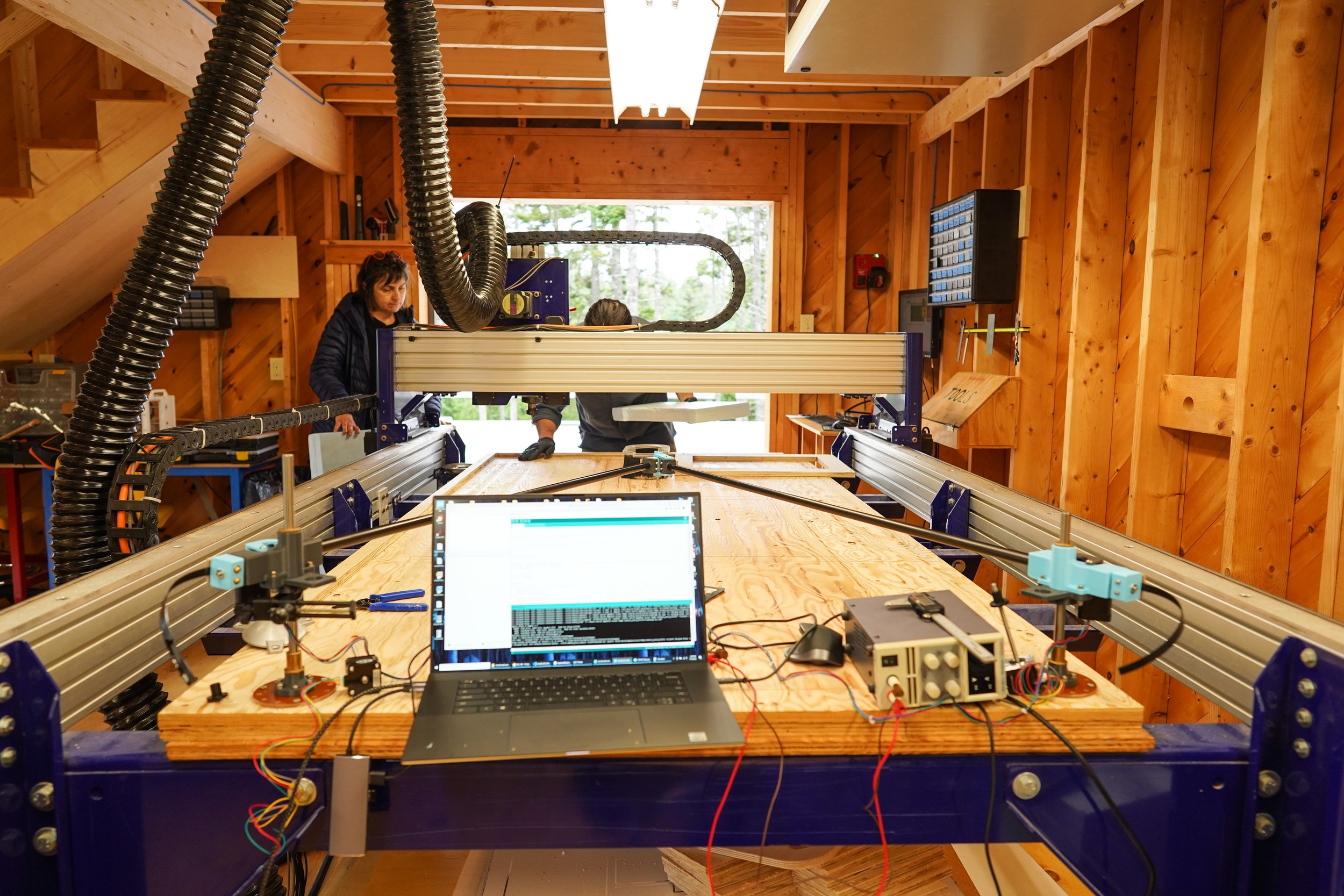

THE HAYSTACK FAB LAB

A cutting-edge digital fabrication and technology studio.

Haystack’s Fab Lab was established in 2011 and has quickly become an integral part of our mission to think broadly about the field of craft. Fab Labs, an educational outreach component of MIT’s Center for Bits and Atoms, are an international network of over 2,000 small-scale digital fabrication facilities that spans 100 countries and 24 time zones. Fab Labs provide a connection to a global community of learners, educators, technologists, researchers, makers, and innovators. In 2016, the Haystack Fab Lab was recognized with the Distinguished Educators Award from the James Renwick Alliance, the first ever given to a program for pioneering contributions to craft education.

The Fab Lab complements our existing programs and is available to all residents and session participants. In each session, Haystack invites two people to serve as Fab Lab Residents by partnering with faculty and scientists at MIT, Harvard Graduate School of Design, University of Virginia, RISD, AS220, and other Fab Labs around the world. These residents provide unique perspectives in the areas of digital design, fabrication, and craft to workshop participants and faculty at the school. The culture found in the Haystack Fab Lab is one of experimentation, risk-taking, and collaboration.

During the winter months, the Haystack Fab Lab serves as a vital resource for community-based education, outreach, and digital fabrication training. We have been building capacity to expand our work within the local school system on Deer Isle and around the broader Blue Hill Peninsula, by integrating digital technology and design proficiency into area classrooms.

For additional information about the Haystack Fab Lab, including machine specifications and capabilities, please contact fablab@haystack-mtn.org.

3D PRINTERS

4 - Prusa i3 MK3S

2 - Prusa Mini

Flashforge Dreamer Dual Extruder

Sindoh 3D Wox Filament Printer

Formlabs Form 2 SLA/Resin

CNC MILLS

Shopbot PRS Alpha | 4’ x 8’

Shopbot Desktop | 18” x 24”

Bantam Precision PCB Mill | 6” x 4”

Shaper Origin Handheld CNC Router

DIGITAL EMBROIDERY

Brother SE 1800

DIGITAL MEDIA

HP DesignJet 111 Large Format | 24”

Epson ET-2550 | Inkjet

Canon TR8620 | Inkjet

ELECTRONICS

Electronics Bench with Soldering Equipment,

Oscilloscope, Power Supply, and a Full

Range of Components

LASER CUTTERS

Universal VLS 6.75 60-Watt | 32” x 18”

Universal VLS 3.50 50-Watt | 24” x 12”

Epilog Legend 24TT 35 Watt | 24” x 12”

VINYL CUTTERS

Roland GX-24 | 24”

4 - Silhouette Portrait | 12”

Heat Press

PLASMA CUTTER

Forest Scientific MakerFab | 4’ x 4’

DESIGN SUITE

5 - iMac Workstations

Adobe Creative Suite

Fusion 360

Inkscape

Rhino

COVID-19 PPE Project

In response to the growing impact of the pandemic and shortages of personal protective equipment (PPE) for essential workers, Haystack’s Fab Lab helped produce and deliver supplies to our community.

In late March 2020, Haystack made the difficult decision to suspend all of our programming for the entirety of the season. Soon after this decision was made, the Haystack Fab Lab switched gears to producing PPE in response to the Coronavirus pandemic.

Staff in the Haystack Fab Lab produced medical face shields and surgical mask strap “ear savers” for community organizations. We prioritized efforts for Hancock County and the surrounding area in Maine.

Learn more about the COVID-19 PPE Project

FAB LAB PROGRAMS

FAB LAB RESIDENTS

Fab Lab Residents are experts in their respective fields and come to Haystack from partnering labs across the country and internationally. Invited to work for the school each session during the summer, Fab Lab Residents provide one-on-one consultations, small group tutorials, and demonstrations, while modeling advanced workflows and processes related to their own work. 2024 Residents coming soon.

FAB LAB INTERNSHIPS

Beginning in 2018, Haystack established a paid internship program for area high school students. Interns assist in running the Fab Lab on the Haystack campus, help session participants, and shadow volunteers that oversee the lab. Job training and exposure to participants and faculty from across the US and abroad make for a rich and impactful experience.

HAYSTACK LABS

Haystack Mountain School of Crafts and the MIT Center for Bits and Atoms developed and piloted an experimental residential program July 12-16, 2021 that combined artists and scientists to take over the campus and explore the integration of emerging technologies and processes for craft. 12 projects emerged from the week, based on their success this is expected to become a recurring event.

HAYSTACK COMMUNITY LABS

The Haystack Community Labs offer diverse programs and workshops that extend beyond digital design to embrace traditional craft techniques. These activities emphasize skill development, knowledge exchange, and innovation–fostering inspiration within the local community and nurturing future makers, artists, and designers.

CREATIVE MAKERS COLLABORATIVE

Haystack Mountain School of Crafts, Pioneer Prize, and Project Launch are partnering to develop and implement a new after-school program for Blue Hill Peninsula and Deer Isle high school students. This program will expose students to a range of exciting areas of technology through hands-on experience with support and mentorship.

PIONEER PRIZE

A community competition encourages local high school students to develop and innovate STEAM projects. Community members have established the Pioneer Prize to motivate and celebrate the remarkable capacity of our young people to forge new pathways of economic opportunity. The prize gives away $5,000 in cash prizes each year to three students.

Haystack is a proud member of the Fab Lab Network, a global creative community located in more than 100 countries with nearly 2,000 Fab Labs across the globe.

In partnership with The Center for Bits and Atoms, Massachusetts Institute of Technology.